APR-RecyClass Cooperation Report

INTRODUCTION

In March 2023, The Association of Plastics Recyclers (APR) and RecyClass signed a cooperation agreement, for a duration of 3 years, with the objective to drive global harmonization on Design for Recycling of plastic packaging. While both organizations represent a different geographical market, there are many similarities between them including a united goal to recycle more plastics to reduce waste and facilitate the transition toward a circular economy. Both organizations are non-profits and are the only organizations in their respective regions representing the entire plastics recycling industry.

Both APR and RecyClass strive to build design for recycling guidance for the plastic packaging industry based on scientific findings and following a fact-based approach. Through their work, the two organizations address packaging materials and format-specific Technical Committees consisting of experts from across the supply chain focused on specific recycling streams.

Further details for each organization include:

- APR is a North American based association whose core membership are the plastics recyclers and reclaimers with affiliate members representing of all steps in the plastic packaging supply chain including raw material suppliers, converters, retailers, consumer package groups (CPGs), etc. The APR developed their first APR Design® Guide for Plastics Recyclability in 1994 dedicated to PET and HDPE rigid packaging. Over the years, this document has expanded to include PP rigid, PE flexible and PP flexible packaging and continues to provide guidance to packaging designers to ensure their packaging is compatible with the recycling infrastructure, thereby increasing the quality of recycled plastics and increasing efficiency of the recycling process. The “Design Guide” also integrates testing protocols to allow innovators to test the effect of their packaging innovations on the recycling, sorting, and processing infrastructure.

- RecyClass is a non-profit, cross-industry initiative advancing recyclability, bringing transparency to the origin of plastic waste, and establishing a harmonised approach toward recycled plastic calculation & traceability in Europe. RecyClass develops Recyclability Evaluation Protocols and scientific testing methods for innovative plastic materials which serve as the base for the Design for Recycling Guidelines and the RecyClass Online Tool. RecyClass established Recyclability Certifications for plastic packaging, Recycling Process Certification and Recycled Plastics Traceability Certification for plastic products.

Information developed by APR & RecyClass is essential to helping build and scale a circular economy for plastic packaging. Their guidance and testing protocols help brand owners, converters and other packaging specifiers understand how to optimize plastic packaging design for the recycling industry and maximize circularity. Additionally, this information supports other organizations that are stakeholders in developing a circular economy such as NGO’s and policy makers.

To ensure optimal cooperation and sharing of information to avoid duplicating work, RecyClass and APR teams agreed to have their staff members in charge of their respective technical committees participate in the equivalent technical committee of the other organization. New findings were communicated through the Design for Recycling guidelines and via press releases or webinars. In that regard, APR and RecyClass hosted joint webinars, and participated in common panel discussions in multiple conferences to spread the message of a global harmonization effort.

Objectives of the cooperation

APR & RecyClass cooperation is driven by the idea of promoting global harmonization and proposing solutions to the plastic packaging industry on how to design recyclable plastic packaging. The main objectives of this cooperation began with the transfer of knowledge and scientific data from one organization to the other to close the gap between the Design for Recycling guidelines with the following objectives:

- Develop a unified set of design for recycling guidelines to facilitate plastics circularity.

- Work towards alignment of the Recyclability Evaluation Protocols (RecyClass) and Critical and Application Guidance (APR) based on comparative data obtained by testing identical packaging features and innovations according to APR & RecyClass testing procedures.

- The long-term objective is to have both organizations delivering approval letters (RecyClass) or recognition letters (APR) based on both recyclability protocols

- Better align the approach and protocols to evaluate the sorting efficiency of plastic packaging.

This update builds on the progress reported in our 2024 APR-RecyClass Cooperation Report published in March 2024.

Design for Recycling Guidelines and Recyclability Methodology

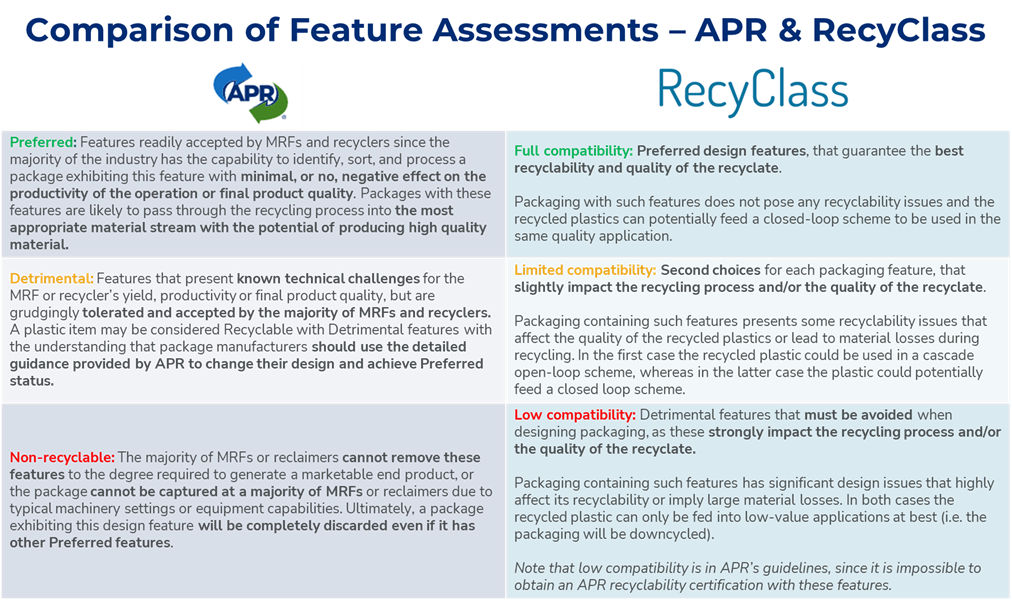

According to APR and RecyClass definition of recyclability, both APR and RecyClass developed Design for Recycling Guidelines on the base of testing results by using their own recyclability testing protocols Both set of guidelines are based on a green, orange, & red traffic-light color to represent the different levels of compatibility with recycling of each plastic packaging feature, being respectively full, limited and low/no compatible. The descriptions of the categories are given in the following table. While they are quite similar, subtle differences exist, which translate to differences within APR and RecyClass’s respective guidance. Elucidating and narrowing these minor differences is within the scope of the cooperation.

Both organizations utilize the categorization of each design feature to build full plastic packaging recyclability assessments. RecyClass developed a European methodology to assess (free online RecyClass Tool) and certify (via third-party audits) recyclability based on:

- the Recyclable Plastic Content

- the Design for Recycling Guidelines

The RecyClass assessment results in a class grading (A to C) indicating the level of recyclability which can be impacted by each individual factor of a packaging design. Only classes A, B and C are considered recyclable. Each recyclability class is linked to a minimum recyclable plastic content (i.e. 95% for A, 80% for B and 70% for C). Packaging with class “A” (i.e. recyclable plastic content ≥ 95wt% and all features listed as fully compatible in the guidelines) can be recycled in closed-loop systems, for instance “bottle-to-bottle” or “film-to-film”. APR has full packaging self-assessment using a green, orange, & red traffic-light color scheme with a Preferred Design for Recycling classification indicating the best opportunity for circular applications. While there is some overlap with RecyClass’s B and C across APR’s “Tolerated but Needs Improvement”, the approximate alignment between the two whole package assessments is shown in the figure below.

A difference between APR and RecyClass lies in the end application for recycled plastic where RecyClass targets high quality recycled plastic to feed bottles-to-bottles and films-to-films circular applications, as a benchmark. On the other hand, APR is open to consider as recyclable a packaging that can be technically recycled and the recycled plastic can be used in an equivalent packaging application or in non-packaging applications (i.e. pipes, fibers).

Due to the recent approval of the Packaging and Packaging Waste Regulation (PPWR), imposing all packaging to be recyclable by January 2030 by means of 3 Recyclability Performance Grades A, B, C, RecyClass recently updated its recyclability methodology in alignment with the PPWR. By adopting the new framework, RecyClass ensures that only the recyclability classes A, B, and C are considered (i.e. D, E, F were canceled), reflecting a more stringent and harmonized approach to assessing packaging recyclability. This alignment enhances transparency, supports the circular economy, and provides clearer guidelines for the industry to improve packaging design in line with evolving regulatory requirements.

HDPE and PP Rigid Packaging

Harmonization steps achieved in 2023

Significant progress was evident after one year of cooperation, with key achievements in harmonization and alignment, including:

- EVOH: RecyClass shared testing results; APR approved thresholds and tie layer requirements in accordance with RecyClass recommendations.

- PE Closures: APR shared their guidance; RecyClass endorsed them and updated the Design for Recycling Guidelines accordingly.

- Density Limit: APR adopted RecyClass’s 0.97 g/cm³ maximum for polyolefin rigid packaging.

Harmonization steps achieved in 2024

During 2024, significant progress was made in aligning key design for recycling criteria between APR and RecyClass, addressing previously identified discrepancies. The main changes in regard to the Design for Recycling Guidelines are listed below:

- Foamed Olefinic Parts: RecyClass testing led to a unified approach in guidelines, confirming these materials as compatible with HDPE and PP recycling.

- EVA in Closures: RecyClass updated guidelines to align with APR’s approach, considering EVA fully compatible with HDPE and PP recycling.

- TPOs & TPSs: RecyClass testing enabled alignment with APR’s recommendations on their use in HDPE & PP packaging, recognizing their use in HDPE and PP packaging as preferred by APR.

- Density: APR updated their density guidance to be in line with RecyClass.

Moreover, an important step in the collaboration between both organizations was the performance of two joint tests, one on HDPE packaging and the second one on PP packaging. In these tests, the packaging was subjected to both APR’s and RecyClass’ protocols in parallel at the same testing facility. The test reports indicated that certain aspects of the protocols might require alignment to promote potential mutual recognition in the future.

The main aspect to highlight relates to the filter pack used, which may lead to different results when assessing the extrusion process. Based on these findings, APR has concluded that aligning with RecyClass’ filter pack was necessary, closing the gap in this aspect and facilitating a potential future two-way recognition of test reports. Additionally, with the completion of two parallel testing protocols, IKTR has been recognized as an APR Candidate testing lab for HDPE and PP rigid. This expands the testing options for innovators seeking to receive both APR and RecyClass recognitions.

Work in progress

Continued comparison of testing protocols

While the differences in testing protocols were seen to be minimal, currently, there is only one common test performed respectively for each rigid polyolefin material and further parallel evaluations may reveal additional differences that need to be resolved. Companies are encouraged to submit their packaging in 2025 to help identify and address any remaining gaps in both procedures.

Guidance updates

There are several ongoing programs in both organizations to further work towards harmonized guidance for rigid polyolefin packaging. For example:

RecyClass

- Work on colour thresholds for natural and white HDPE and PP rigid packaging.

APR

- Inclusion of dispensers in the 10% maximum polyolefin contamination in packaging aligning with RecyClass closure guidance.

- Development of clear/natural PP guidance based on RecyClass guidance.

- Recognition of additional testing facilities in Europe.

- Air elutriation

- APR is developing an air elutriation calibration process that has been evaluated by European testing facilities with future incorporation into RecyClass guidance in mind.

- Once testing is standardized, guidance regarding maximum elutriation losses for each category (Preferred, Detrimental and Non-recyclable) will be developed and shared with RecyClass.

- Learnings from RFID labels that have received APR Critical Guidance Recognition will guide guidance development and be shared with RecyClass.

Challenges and opportunities for future harmonization

A topic of misalignment today is the use of hot wash temperatures in the APR Critical Guidance Protocols for certain applications. Higher wash temperatures are sometimes used in North America as required for processes that have received an US Food and Drug Administration (FDA) Letter of No Objection (LNO) and/or Bureau of Chemical Safety within the Food Directorate of Health Canada’s Letter Of No Objection (LONO) for food contact applications. As there are currently no postconsumer mechanically recycled polyolefins that have received food contact approval by EFSA, the wash temperatures used in Europe are lower to conserve energy. Nonetheless, in view of the requirements established by the PPWR in terms of minimum amount of recycled content in contact sensitive packaging by 2030 and the development of novel technologies in Europe to recycle PP and HDPE back to this type of applications, RecyClass is working (in the context of the European Project STOPP) on the development of Design for Recycling Guidelines and Testing Protocols for contact sensitive PP and HDPE packaging, which may bring together the procedures used nowadays by APR with the ones to be developed by RecyClass.

PE and PP Flexible Packaging

Harmonization steps achieved in 2023

Already significant progress could be seen after 1 year of cooperation. Among the harmonization or better alignment, one should mention the following achievements:

- On testing protocol for PE films:

- RecyClass is recommending producing both 50 and 25 µm films. Like APR, the 50 µm film will be used for mechanical performance characterization.

- On Gels & Specks characterization, RecyClass now also recommends following APR procedure to evaluate the quality of PE films, through their FAR Rating approach.

- Washing steps, which was mandatory for RecyClass assessments in the past, became optional depending on the nature of the innovative feature to evaluate. Since APR does not request a washing step for PE films, this allows for similar pre-treatment steps.

- On Design for Recycling guidelines:

- After test campaigns and consultation with the entire value chain, APR and RecyClass are now providing the same recommendations related to EVA, Ethylene-based copolymers, and ionomers.

RecyClass adopted FAR Rating Approach to Match APR’s PE Film Critical Guidance Protocol

Harmonization steps achieved in 2024

In 2024, the following actions were done in order to further bridge the gap between both organisations, and get closer to harmonized guidelines and protocols:

- RecyClass and APR decided to join forces to better understand the impact of laminating adhesives and inks on the recyclability of PE films. While both organisations will be performing separate test campaigns, discussions took place on the Design of Experiments of the new test campaigns. Data from previous test campaigns were shared in order to compile results and improve analyses.

- The first APR-RecyClass common tests were performed on specific innovations for PE films according to respective testing procedures. These can be used as a starting point for the comparison of the two recyclability evaluation protocols.

- While no alignment could be found on nitrocellulose-based (NC) inks, APR updated its recommendation warning about the use of NC-inks on flexible packaging based on RecyClass testing results. Better harmonization could happen based on the results of the ongoing test campaign from APR.

Work in progress

The harmonization testing program started by both organisations at the end of 2023, aiming at generating comparative data obtained via both APR and RecyClass protocols is still ongoing, with several tests being performed in different laboratories in Europe and North America.

On laminating adhesives, information was shared between the two organizations, but because of the use of different control materials, it was impossible to reach an update of APR Design® Guide, or achieve alignment with current RecyClass recommendations.

A collaboration and information exchange on inks, and electron-beam treatment is underway, with similar objectives. For inks, the purpose remains to update Design for Recycling Guidelines with the level of recyclability of different ink binder chemistries (PU, PVB, NC, Acrylics, …). For electron-beam treatment, the main objective is to identify the acceptable treatment conditions that will not hamper the quality of the recyclate (crosslinking, gels, haze), There is also a potential to more closely align guidance on EVOH use in PE film as APR is in the process of reviewing test data and comparing with RecyClass.

Challenges and opportunities for future harmonization

Based on the complexity of PE flexible packaging and differences in collection mechanisms and processing, a lot of work still needs to be done to support the industry in the development of future recyclable packaging. Both APR and RecyClass align on the fact that features such as inks, barrier materials or adhesives will all be challenging components to address, and that they should be prioritized to deliver better, more aligned, Design for Recycling recommendations.

PP flexible packaging has not previously been collected in North America due to a lack of infrastructure, regulations supporting its collection, and markets for the recycled output. With the emergence of new regulations and EPR programs, these materials will begin to be collected in Canada in 2025. APR’s Film Technical Committee published preliminary Design Guidance for PP films, which currently differs from RecyClass Design for Recycling Guidelines, since more development of the stream and end markets is needed. The APR Film Technical Committee will study RecyClass’s PP flexible testing protocols as APR develops its own PP film test protocol once end-market requirements are better understood.

PET Bottles and Trays

Harmonization steps achieved in 2023

Comparison of APR Critical Guidance and RecyClass Recyclability Evaluation Protocols

In 2023, RecyClass developed new Recyclability Evaluation Protocols for PET bottles and for labels & adhesives applied on PET bottles, based on the State-of-the-art of European PET recycling processes. For these new testing methods, RecyClass utilized APR’s Critical Guidance testing protocols as a starting point in the development of their Recyclability Evaluation Protocols for PET bottle packaging. In that regard, both Critical and Application Guidance of APR and RecyClass Recyclability Evaluation Protocols are very much aligned, with only a few differences, such as stirring speed during washing, benchmarks for characterization, or small variations in processing temperatures. As these are minor deviations, both organizations strongly believe that through common testing, and data-based discussions, these protocols will continue to get closer in the future.

RecyClass utilized APR’s Critical Guidance testing protocols as a starting point in the development of their Recyclability Evaluation Protocols for PET bottle packaging.

Comparison of Design Guidance given by RecyClass and APR

A review of PET guidance documentation from each organization reveals, in most cases, that the factual content and topics covered are very similar. There are differences in editorial style and level of detail given. There are only a couple of cases where divergent information is presented.

Following are three summary comparisons to illustrate the guidance given by each organization for PET containers:

- Container Material – RecyClass recommends the use of 90% of PET in a packaging. APR calls for PET resins that meet a few specific criteria and currently has no guidance speaking to minimum PET content.

- Closures and Liners – RecyClass provides a concise listing of materials that can be used in closures, liners and dispensing valves. This list includes floating silicone materials that are considered as limited compatible with PET recycling. APR provides a broader definition of olefin and other materials that are acceptable, based on their density, but this list does not include floating silicones specifically.

- Labels and Inks – While much of the guidance is similar, APR and RecyClass differ in the level of detail of key requirements. RecyClass gives more direct guidance on label density, ink composition, and direct printing limits while APR focuses on the combined impact of label components. APR and RecyClass guidance are also not completely aligned regarding NIAS in inks and adhesives, as well as wastewater disposal standards, as they differ between Europe and North America.

Harmonization steps achieved in 2024

Some actions were completed to improve alignment on recyclability testing and design recommendations between both organizations. The following points can be underlined:

- On floating silicones, APR is now recommending testing such solutions, which are not identified as optimal choices. RecyClass is also recommending moving from floating silicones to thermally processable polyolefin TPO solutions.

- On PET Thermoforms, APR published the “PET Thermoform Packaging Design Resource Document”, where several similar design recommendations are comparable or identical to the ones given in RecyClass Design for Recycling Guidelines for PET Thermoforms. A full alignment is not present yet, but both organisations share the same objective, being to have all contaminants (non PET elements) removed from the PET trays before or during the recycling process.

- Regarding recyclability evaluation procedures, steps toward harmonisations were done in 2024, in particular with the alignment of benchmark recommendations on IV and other parameters.

Work in progress

In 2024, both organizations identified four technical programs that will be especially impactful for any region engaged in PET container recycling. While APR and RecyClass looked for opportunities to co-invest in the following four technical areas, progress has been made to maximise the efficiency of the cooperation.

- Improving alignment of clear and light translucent blue PET definition through creation of an APR working group which seeks to examine and potentially validate the RecyClass definition through survey of North American reclaimers and sortation testing.

- Better managing the impact of labels, adhesives, and inks when PET is recycled. In 2024, both APR and RecyClass started revision work of their testing procedures for labels and adhesives on PET bottles. While this work is ongoing, the objective is to close the gap between the current testing methods, and facilitate common recognition of labelling systems by both organizations simultaneously.

- Regarding inks, RecyClass started investigations to revise its testing method to evaluate the behavior of inks during washing treatment

- Creating tests to evaluate the recycling impact of additives commonly used in PET. APR and RecyClass teams worked on identifying the different categories of additives present in PET packaging and estimating the most concerning features that could degrade the rPET in terms of color. Each organization decided to focus on a different category to maximize efficiency in addressing the range of additives. RecyClass will focus on reheat additives and APR on toners.

Overall, in 2025, RecyClass and APR will be continuing to work on many crucial topics to improve rPET quality and facilitate the testing of innovative materials. In general, the focus whould remain on developing equivalent test methods for clear PET bottles that are harmonized and compliments and supports design guidance.

Challenges and opportunities for future harmonization

The MRF sortation and reclaiming process steps associated with PET packaging are virtually equivalent in Europe and North America. So, it is logical that design guidance and recycling evaluation tests can be similar, if not exactly the same, for each region. But today’s guidance and test methods do have some distinct differences that must be resolved in a harmonization effort. One such difference is RecyClass’s specific design guidance for PET thermoforms/trays. As thermoforms are collected in thermoforms specific bales in Europe, the guidance varies from the North American case where thermoforms are primarily comingled in PET bottle bales. This will be a future point for discussion and harmonization.

Next Steps of the Cooperation

While the first year of cooperation highlighted that similar challenges are faced in both continents regarding Design for Recycling, and that harmonization is necessary to deliver more consistent guidance to the industry, the second year of the cooperation saw a significant increase of exchanged information and data to close the gap on some topics. It remains evident that there is still a lot of work to do to better align design for recycling recommendations, in particular for flexible packaging. In this context, multiple test campaigns are performed by both APR and RecyClass to generate scientific data on current misalignements. Both organizations remain optimistic about delivering a common message to the industry in the coming years, and therefore avoiding duplication of recyclability tests in Europe and North America. Nevertheless, this cooperation can also be improved to gain efficiency and avoid contradictory recommendations in the future. As this cooperation needs to remain fact-based and rely on recyclability tests data sharing, both APR and RecyClass will work actively on better coordinating their testing programs to support the industry with more harmonized design for recycling recommendations and joint test campaigns.

Both organizations remain optimistic about delivering a common message to the industry.

Acknowledgments

APR and RecyClass teams would like to thank our combined membership organizations for their support in this effort, especially those that have tested their products in the parallel testing streams. We would also like to thank our Working Groups and Technical Committees that have spent countless hours reviewing and approving guidance changes based on research and data collected by the other organization. We would also like to thank our teammates within our organizations for their support in the development of this report.

APR & RecyClass Ambassadors

- Alex Kazakov (APR)

- Augusto Bruno (RecyClass)

- Carolane Gerbehaye (RecyClass)

- Curt Cozart (APR)

- Fabrizio Di Gregorio (RecyClass)

- Jean-Emile Potaufeux (RecyClass)

- John Standish (APR)

- Megan Moore (APR)

- Rebecca Mick (APR)

- Scott Trenor (APR)